In both daily life and industrial production, storage boxes play an indispensable role. They assist us in organizing items, optimizing space utilization, and ensuring the safety and protection of our belongings. Among various types of storage solutions, rotationally molded boxes stand out due to their unique manufacturing process, exceptional performance, and extensive range of applications.

This article will delve into the production techniques, performance advantages, and diverse applications of rotationally molded boxes, revealing the distinctive appeal of this storage container.

Manufacturing Process of Rotational Molding Boxes

The manufacturing process of rotational molding boxes primarily relies on the technology of rotational molding, which is a method for forming thermoplastic materials. The rotational molding process involves filling molds with plastic powder or granules, followed by heating and simultaneous rotation of the mold. This allows the plastic material to melt uniformly and adhere to the inner walls of the mold. Once the plastic has completely melted and conformed to the mold, it is removed from the heating zone for cooling, resulting in a finished rotational molding box. A critical aspect of this process lies in the design and fabrication of molds. The quality of molds directly influences both the shaping effectiveness and performance characteristics of rotational molding boxes.

High-quality molds should possess excellent thermal conductivity, durability, and high-precision machined surfaces to ensure dimensional accuracy, uniform wall thickness, and surface smoothness in the final product. Furthermore, the rotational molding process encompasses several steps including raw material pretreatment, loading materials into molds, heating, rotating, cooling, and post-processing. Each step requires stringent control over processing parameters to guarantee that both quality and performance standards are met in the final product.

Performance Advantages of Rotational Molding Boxes

Rotational molding boxes, due to their unique manufacturing process, possess a series of outstanding performance advantages: Seamless Structure: The rotational molding process enables the box body to be formed in one piece without seams, thereby enhancing overall strength and durability. Uniform Wall Thickness: The consistent heating and cooling during the rotation process ensure uniform wall thickness throughout the box, improving product reliability and stability.

Lightweight yet High Strength: Rotational molding boxes are typically made from lightweight high-strength materials such as polyethylene (PE) or polypropylene (PP), making them easy to handle and transport while also providing excellent load-bearing capacity. Strong Weather Resistance: These boxes maintain stable performance under extreme weather conditions, exhibiting resistance to aging and deformation, thus offering reliable protection for users.

Diverse Design Options: The rotational molding technique allows designers to create boxes in various shapes, colors, and internal structures, catering to the personalized needs of different consumers.

Applications of Rotational Molding Boxes

Rotational molding boxes have emerged as a preferred storage solution due to their exceptional performance and diverse application areas. Below are the various fields in which rotational molding boxes are utilized Logistics and Transportation.Rotational molding boxes possess robust durability and waterproof characteristics, making them highly suitable for packaging and storage in logistics and transportation. They effectively protect goods from damage while facilitating easy handling and stacking.

Warehouse Management:These boxes can be customized to accommodate different sizes and shapes of products, optimizing warehouse space utilization and enhancing management efficiency.

Medical Equipment: The application of rotational molding boxes in the medical equipment sector is extensive. They serve as secure storage for medical instruments, pharmaceuticals, and biological products, ensuring safety and reliability.

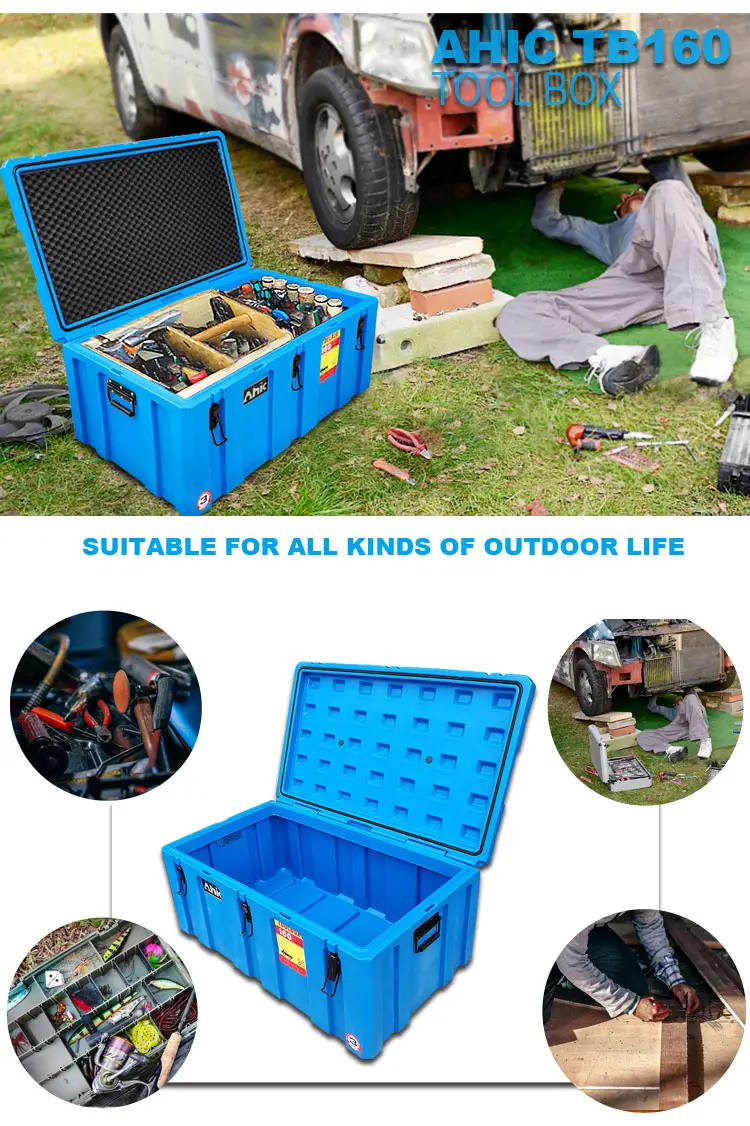

Outdoor Exploration: With their lightweight yet high-strength design coupled with excellent weather resistance, rotational molding boxes are ideal for storing and transporting gear during outdoor adventures. They can hold various exploration equipment and food supplies, providing adventurers with convenient and safe storage solutions.

Military Equipment: In the realm of military operations, rotational molding boxes play a crucial role by serving as containers for storing and transporting military supplies, equipment, ammunition, etc., thereby ensuring the smooth execution of military missions.

Future Outlook of the Rotational Molding Box Industry

With the continuous advancement of technology and the growing demand for storage solutions, the rotational molding box industry is poised for a promising future. In the coming years, there will be an increased emphasis on environmental protection and sustainable development within this sector.

Manufacturers are expected to adopt more eco-friendly materials and production processes to minimize their impact on the environment. Additionally, designs for rotational molding boxes will become increasingly intelligent and personalized to cater to diverse consumer needs. Furthermore, the application areas for rotational molding boxes will continue to expand, providing efficient, safe, and reliable storage solutions across various industries.

In summary, due to its unique manufacturing process, outstanding performance, and extensive range of applications, rotational molding boxes have emerged as leaders in storage solutions. As technology progresses and demand continues to rise in the future, these products will maintain their significant role in enhancing convenience and comfort in both personal lives and professional environments.