Rotational Molding Process Introduction

There are many processing and molding techniques for plastics and composite materials. In addition to common methods like extrusion molding, injection molding, and blow molding, rotational molding is also a processing method for plastic products. Also known as rotomolding or rotational casting, it is a plastic molding process.

Rotational molding involves adding plastic material into a mold, which then continuously rotates along two vertical axes while being heated. Under the influence of gravity and heat, the plastic material gradually and evenly coats, melts, and adheres to the entire surface of the mold cavity, taking the desired shape. It is then cooled and solidified into the final product. Currently, the rotational molding industry is developing rapidly abroad. In China, due to factors such as relatively slow processing cycles and material limitations, its development pace lags behind other plastic molding industries. It should be noted that rotational molding has low production efficiency, with a typical product requiring 30 to 60 minutes for molding, cooling, and mold handling. Production volume depends on the number of molds, as multiple molds can be processed simultaneously on one machine.

Characteristics of Rotational Molding

1. Low mold cost: For products of the same specification, rotational molding mold costs are about 1/3 to 1/4 of those for blow molding or injection molding.

2. Good edge strength: Rotational molding can achieve edge thickness exceeding 5mm, effectively solving the issue of thin edges in hollow products.

3. Capable of incorporating various inserts.

4. Products can have very complex shapes with wall thickness exceeding 5mm.

5. Can produce fully enclosed products.

6. Products can be filled with foam material for insulation.

7. Wall thickness can be freely adjusted without modifying the mold.

8. Products are seamless and hollow with uniform wall thickness, which can be adjusted to achieve high strength.

9. Supports various surface textures, colors, UV-resistant and anti-aging treatments, and stone or wood simulation effects.

Applications of Rotational Molding Technology

Currently, rotational molding products are used in transportation, traffic safety facilities, entertainment, river and waterway dredging, construction, water treatment, pharmaceuticals and food, electronics, chemicals, aquaculture, textile printing and dyeing, and other industries.

1. Container-type rotational molded parts, widely used for water storage tanks, chemical storage tanks (e.g., for acids, alkalis, salts, chemical fertilizers, pesticides), fuel containers (e.g., gasoline tanks, automotive and aircraft fuel tanks), and battery casings.

2. Automotive rotational molded parts, mainly using polyethylene and polyvinyl chloride resins for components such as air conditioning ducts, seat backs, and armrests.

3. Sports equipment and substitutes, primarily including polyvinyl chloride rotational molded parts such as water balls, buoys, bicycle seats, small boats, and dock buffers. Surfboards and small boats are also rotational molded products.

4. Toys, mannequins, and crafts. Due to the ability to create molds using precision casting or electroforming, rotational molding can replicate fine details from the mold surface, making it suitable for highly aesthetic products like toys, mannequins, and crafts. Beyond these, rotational molding is also widely used for various boxes, casings, and large pipes, such as storage bins, trash cans, machine covers, protective housings, lampshades, bathroom units, phone booths, and yachts. Rotational molded products are extensively used in liquid chemical storage and transport, chemical plants, industrial coating, rinse tanks and reaction vessels in rare earth extraction, as well as maritime buoys and domestic water tanks.

Main Advantages of Rotational Molding

(1) Suitable for molding large and extra-large parts. Most plastic molding processes, such as widely used injection molding, compression molding, extrusion, and blow molding, subject both the plastic and mold to very high pressure during forming. Therefore, when producing large plastic parts with these processes, molds capable of withstanding great pressure are required, making the molds heavy and complex. Additionally, the plastic molding equipment must be designed and manufactured to be very robust, which correspondingly increases the difficulty and cost of manufacturing the machines and molds. In contrast, the rotational molding process only requires the frame strength to support the weight of the material, mold, and the frame itself, along with the clamping force to prevent material leakage. Thus, even for molding large and extra-large plastic parts, very heavy equipment and molds are not necessary. The manufacturing of machines and molds is very convenient, with short production cycles and low costs. Theoretically, there is almost no upper limit to the size of parts formed by rotational molding. For example, using rotational molding to produce a polyethylene cylindrical container with a diameter of 1.2m and a height of 1.2m requires a mold made only of 3mm thick sheet steel formed by cold working and welding, and the rotational molding frame is welded from No. 8 channel steel. Producing such a large plastic container by blow molding would be impossible without very expensive and large-scale blow molding equipment.

(2) Suitable for the production of multi-variety, small-batch plastic products. Since the molds used in rotational molding are not subjected to external forces, they are simple, low-cost, and easy to manufacture, making product changes very convenient. Additionally, rotational molding equipment offers great flexibility. A single rotational molding machine can accommodate either one large mold or multiple small molds. It can simultaneously mold parts of different sizes and even parts with vastly different sizes and shapes, as long as the raw materials used are the same and the part thicknesses are comparable. Therefore, rotational molding offers greater flexibility compared to other molding methods.

(3) Easy to change product colors. In rotational molding, material is directly added to the mold each cycle, and all material enters the product. After the product is removed from the mold, material for the next cycle is added. Therefore, when changing product colors, no raw material is wasted, and no time is spent cleaning the machine or mold. When using multiple molds to produce the same plastic product, different colored materials can be added to different molds to simultaneously produce plastic products in different colors.

(4) Suitable for forming hollow parts with various complex shapes. During rotational molding, the material gradually coats and deposits onto the inner surface of the mold. The product has a strong ability to replicate fine details, such as patterns, from the mold cavity. Furthermore, since the mold is not subjected to external pressure during molding, methods like precision casting can be directly used to create molds with fine details and complex shapes, such as toy or animal molds.

(5) Saves raw materials. Rotational molded products have relatively uniform wall thickness, with slightly thicker corners, allowing for full utilization of the material and saving raw materials. Additionally, there is no waste like runners or gates in the rotational molding process. Once set up, there is almost no scrap material during production, making the material utilization rate of this process extremely high.

(6) Facilitates production of multi-layer plastic products. Using rotational molding, only properly matched materials with different melting temperatures need to be loaded into the mold for molding. The plastic with the lower melting temperature heats and melts first, adhering to the mold to form the outer layer of the part. Then, the material with the higher melting temperature melts on top to form the inner layer. Alternatively, the outer layer plastic can be loaded into the mold and rotationally molded first to form the outer layer, followed by adding the inner layer material and molding to produce the multi-layer rotational molded product. Both methods can be achieved without complex equipment. In contrast, producing multi-layer plastic products by blow molding or injection molding requires special multi-layer molding machines and complex molds.

Limitations of Rotational Molding

(1) Rotational molding is typically only suitable for producing hollow parts or shell-like parts (the latter often obtained by splitting hollow parts). This is because rotational molding relies on the material loaded into the mold gradually melting and adhering to the surface of the mold cavity to form the part. The bulk density of plastic (especially powdered plastic) before molding is generally smaller than after molding. Therefore, except for foamed products, solid parts cannot be produced by rotational molding.

(2) Rotational molding cannot produce parts with widely varying wall thickness or abrupt changes in wall thickness. This characteristic is also directly related to the fact that rotational molding relies on material gradually melting and adhering to the mold cavity surface. To adjust the wall thickness of a part, we can change the heating (increase or decrease) of various parts of the mold to moderately adjust the wall thickness. However, due to the good thermal conductivity of metal molds, this adjustment effect is quite limited.

(3) Rotational molding has difficulty producing parts with flat side surfaces. When the mold rotates, material does not easily settle in flat areas, often resulting in parts with walls that are too thin in flat sections, thereby reducing the part’s effectiveness.

Main Disadvantages of Rotational Molding

1. Relatively high energy consumption. Each rotational molding cycle subjects the mold and mold frame to repeated alternating high and low temperatures, making the process generally more energy-intensive than other plastic molding processes. To reduce energy loss from repeated heating and cooling of the mold, jacket-style rotational molding machines have been developed. These pump hot or cold media through a special circulation system into a jacket around the mold to directly heat or cool it. This equipment significantly reduces the energy consumption of the mold frame, but the mold still undergoes repeated heating and cooling cycles, so energy loss remains high. A notable exception to the high energy consumption of rotational molding is the use of nylon monomer caprolactam to produce nylon parts via rotational molding. For example, using caprolactam to directly rotationally mold nylon 6 parts combines the molding and polymerization processes. The rotational molding occurs below the melting point of nylon 6, and the product can be removed at a higher temperature. Therefore, the mold temperature does not need to be repeatedly cycled through a large temperature range. It is claimed that using caprolactam to rotationally mold nylon 6 parts consumes much less energy than producing nylon 6 parts via blow molding or injection molding.

2. Long molding cycle. During rotational molding, the material is not subjected to strong external forces or intense turbulent flow. It relies solely on gradual heating and melting through contact with the mold cavity surface to adhere to it. After the mold cavity surface is coated with molten plastic, the heat required to warm and melt the inner plastic must be conducted through the molten plastic layer. Plastics generally have poor thermal conductivity, so the heating time for rotational molding is quite long, often exceeding 10 minutes and sometimes even more than twenty minutes. Consequently, the entire rotational molding cycle is relatively long.

3. High labor intensity. In rotational molding, processes like loading material and demolding are not easily mechanized or automated and typically require manual operation, making the labor intensity higher compared to processes like blow molding or injection molding. Dimensional accuracy of products is relatively poor. The dimensions of rotationally molded products are influenced not only by the type of plastic but also by factors like cooling rate, the type and amount of release agent (overall release effect), among others. Therefore, controlling the dimensional accuracy of rotationally molded products is difficult. As a result, rotational molding is only suitable for plastic products without special requirements for dimensional accuracy, such as containers, toys, and similar items.

Material Selection

Common rotational molding materials on the market include: Polyethylene (PE), Polypropylene (PP), Nylon (PA), Polyvinyl Chloride (PVC), Polycarbonate (PC), and others. Materials for rotational molding need to be specially designed, with the most basic requirements including:

1. Easy to grind into powder (or easy to maintain in liquid form), utilizing high-performance ambient or cryogenic grinding mills.

2. Appropriate flowability. Taking the most commonly used polyethylene as an example, the Melt Index (MI, or MFI) of a grade should generally fall within the range of 2 to 10 (g/10 min), with an optimized range of 3-6 (g/10 min). A MI that is too low makes the product difficult to form; a MI that is too high causes the product’s physical properties to decline.

Among materials used in rotational molding, polyethylene accounts for over 90%, with linear low-density polyethylene (LLDPE) making up over 80% of that. The primary reasons are:

Firstly, polyethylene has a broad processing window, making it suitable for prolonged high-temperature environments, which simultaneously reduces the demands on the rotational molding machinery.

Secondly, at room temperature, polyethylene does not react with water, most oils and fats, acids, or alkaline substances, giving it a wide range of applications.

Thirdly, polyethylene raw material is low-cost, facilitating its widespread adoption.

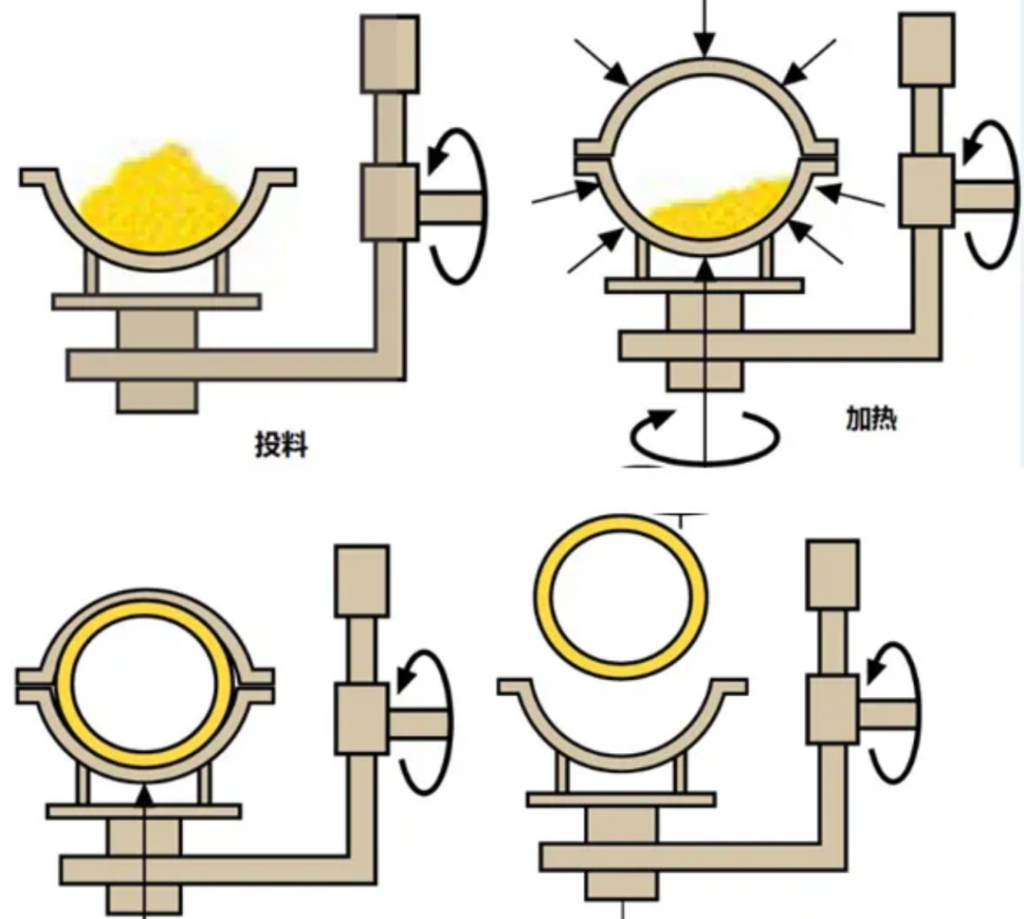

Development of Rotational Molding

Rotational molding is a process method for forming hollow plastic products, also known as rotomolding or rotational casting. The rotational molding process involves adding plastic powder into a mold, then heating the mold and causing it to rotate continuously along two mutually perpendicular axes. Under the influence of gravity and heat, the resin inside the mold gradually and evenly coats, melts, and adheres to the inner surface of the mold, thereby forming the desired shape. The mold is then cooled, and the product is demolded.

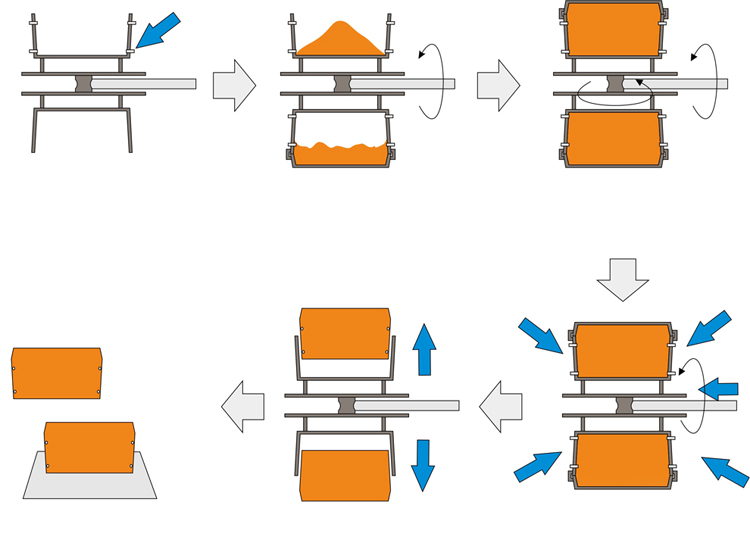

Process Flow of Plastic Rotational Molding

1. Material Pre-treatment: First, suitable plastic raw material is selected, cleaned to remove impurities, and then dried to ensure purity.

2. Material Loading: The pre-treated plastic raw material is loaded into the cylinder of the rotational molding machine.

3. Heating and Melting: The rotational molding machine is started. The cylinder begins to rotate while the heating system heats the material, causing it to melt.

4. Rotational Molding: The melted plastic material, subjected to centrifugal force within the rotating cylinder, evenly coats the inner wall of the cylinder, forming a uniform plastic film. As the cylinder continues to rotate and heat, this film gradually thickens until the predetermined thickness is achieved.

5. Cooling and Solidification: Once the melt reaches the predetermined thickness, heating is stopped and the cooling system is activated to cool the product inside the cylinder, allowing it to harden and set into shape.

6. Demolding: After the product has completely cooled and hardened, it is demolded from the cylinder, yielding the final rotational molded product.

The process is illustrated in the following diagram.

Applications of Plastic Rotational Molding Technology

1. Automotive Components

Rotational molding is widely used for producing large automotive plastic parts, such as fuel tanks, spare tire covers, and fenders. These components typically require high strength and excellent corrosion resistance, which rotational molding can effectively provide.

2. Tanks and Containers

Rotational molding is highly suitable for producing tanks and containers of various specifications, such as chemical storage tanks and water tanks for water treatment equipment. Its capability to manufacture large, hollow structures makes it an ideal process for these types of products.

3. Building Materials

In the construction industry, rotational molding can be used to produce door/window frames, pipes, and panels. These products typically require excellent physical and chemical properties, such as high strength and corrosion resistance, which rotational molding can meet.

4. Toys and Sports Equipment

Rotational molding is also commonly used to produce various toys and sports equipment, such as children’s playground facilities and fitness equipment. These products generally require good elasticity and durability, which rotational molding can provide.

5. Agricultural Products

Rotational molding is also widely used in agriculture, for example in producing irrigation equipment and water storage tanks. Since these products are typically used outdoors, they require good weather resistance and UV protection—properties that rotational molding can provide.