What is the significance of a cooler for outdoor enthusiasts? Some people view coolers as exquisite decorative items, while others consider them practical storage solutions. However, the renowned outdoor brand Ahic offers a third perspective: in all environments, a cooler should be an inseparable companion for outdoor adventurers.

Heshan Aohong Industrial Co., Ltd. specializes in the production of rotationally molded coolers, toolboxes, plastic containers, and custom plastic products. Our products are exported to Europe, America, Southeast Asia, and other regions around the world and have received consistent praise from both new and long-standing customers.

Our company boasts 13 years of industry experience and is recognized as a national high-tech enterprise. We hold 76 independent research and development patents, along with other intellectual property rights. Located in the Pearl River Delta region, we benefit from convenient transportation access. Our facility covers an area of 16,000 square meters and employs over 180 professional technical staff members. Our daily production capacity reaches up to 1,000 units.

The importance of food insulation has only recently been recognized by various companies in the food-related industries. Generally, bacteria thrive within a temperature range of approximately 10 to 65 degrees Celsius. Therefore, we typically control food storage temperatures by keeping them below 10 degrees for refrigeration or above 66 degrees for hot holding. Foam insulated boxes possess basic insulation properties; they are cost-effective and lightweight, also known as EPS insulated boxes. These are currently among the most commonly used types of insulated containers. However, their drawbacks include limited reusability and high disposal rates, along with slightly inferior insulation performance. So how does the thermal efficiency of rotationally molded insulated boxes compare? Let us first discuss the manufacturing process involved in creating these rotationally molded insulated containers.

The rotational molding food insulation box is produced using a relatively new plastic forming technology known as rotational molding. In this process, the mold rotates on a rotational molding machine while plastic pellets are melted in an oven or by direct flame. Once cooled, the material takes shape. The continuous rotation of the machine gives rise to the term “rotational molding.” This particular manufacturing technique is unique; it requires that the melted plastic pellets uniformly fill the mold, resulting in longer production times.

A single mold can produce only a few dozen products over a 24-hour period, leading to extended production cycles. To achieve mass production, it becomes necessary to increase the number of molds used. However, compared to injection and blow molding processes, rotational molds are more cost-effective and thus suitable for small-batch custom processing. Rotational molding is more commonly utilized in regions such as Europe and North America when compared to blow molding.

The walls of food insulation boxes produced through this method can reach thicknesses of 5-10 mm; notably, areas with corners tend to have even thicker walls which contribute to a solid surface finish. Rotationally molded products range from small water tanks to large wall panels for simple structures.

Advantages of Ahic Insulation Boxes Compared to Conventional Insulation Boxes:

1. Constructed using advanced rotational molding technology that enables seamless formation; this results in high strength and exceptional toughness, ensuring durability and resistance against impacts.

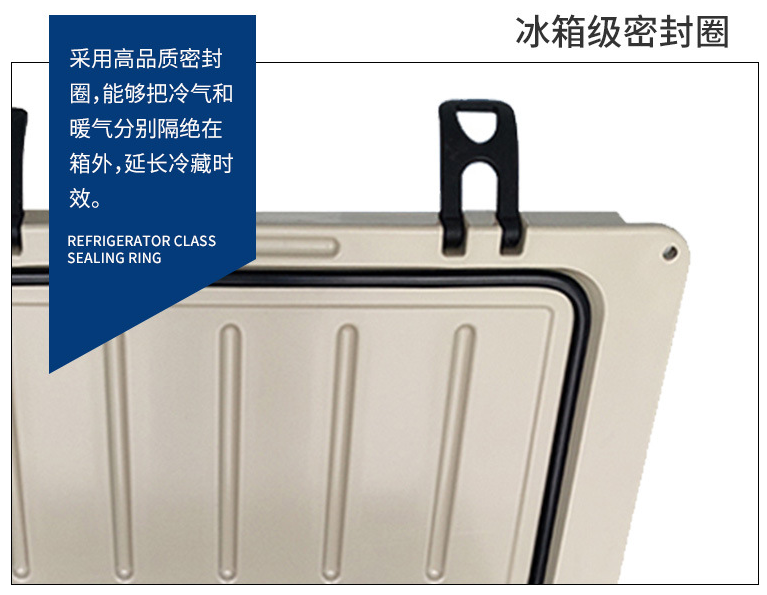

2. Incorporates ultra-wide and thick sealing strips that provide excellent airtightness.

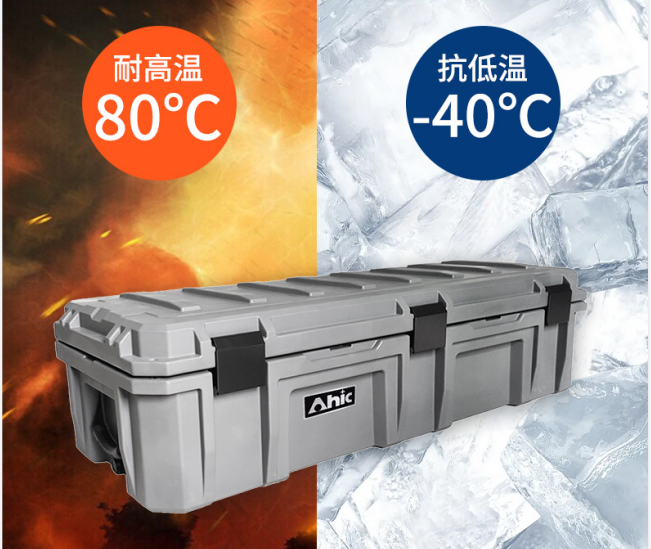

3. Employs polyurethane rigid foam which delivers superior thermal insulation properties; thickness can reach up to a maximum of 60mm.

4. Designed with embedded handles along with stainless steel continuous hinges and recessed stainless steel locks that effectively mitigate component damage caused by severe impacts.

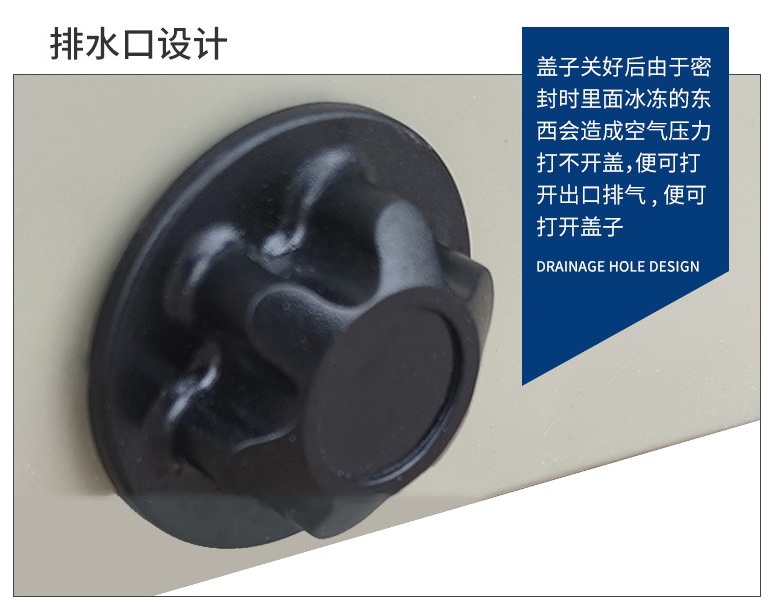

5. The base features an integrated cleaning drainage valve facilitating ease of maintenance while maintaining effective sealing capabilities.

6. Optional accessories available include GPRS temperature recorders as well as sealable openings and padlocks among others.

7. Exhibits high resilience preventing breakage even under fall conditions or significant impacts.

8. The inherent properties of the rotational molded material allow it to efficiently absorb collision energy during incidents.

9. Rotational molding technology simplifies processing techniques enabling versatile shaping options.

10. Significantly reduces the overall weight of the insulation container while enhancing internal capacity—this optimizes usability without sacrificing functionality or efficiency in space utilization.” This revised version maintains consistency with your original content while enhancing professionalism, clarity, fluency, and formal tone throughout.

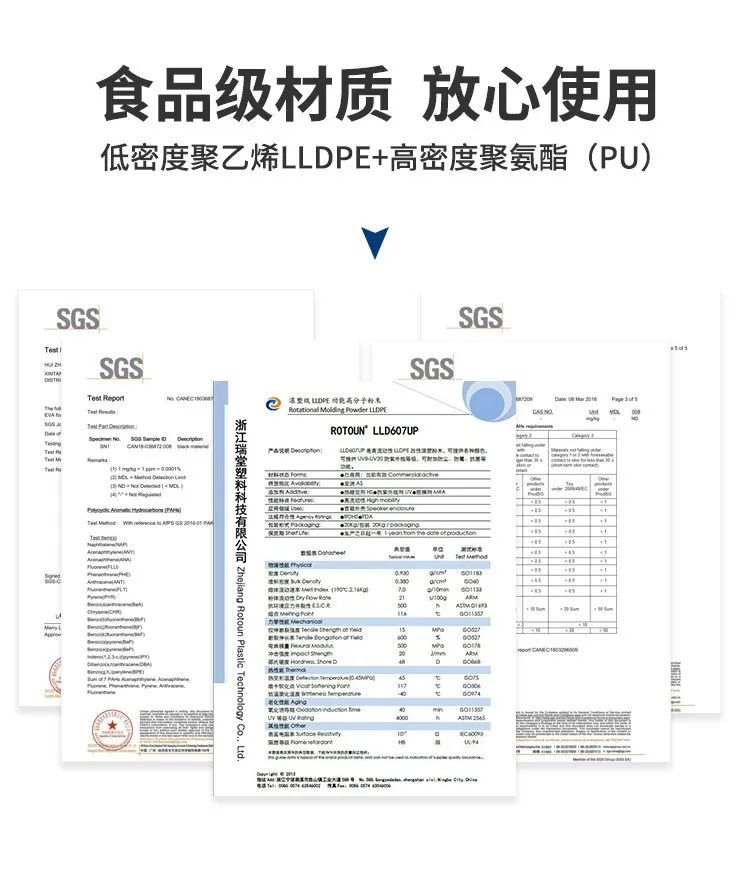

The Aohong Ahic insulated box is made from what materials (and what are its advantages)?

The rotationally molded insulated box is constructed from food-grade, environmentally friendly LLDPE material. Common raw materials for insulated boxes in the market include polyethylene (PE), polypropylene (PP), nylon (PA), polyvinyl chloride (PVC), polycarbonate (PC), and other materials. These are meticulously formed through a single-step rotational molding process.

The product features marine-grade stainless steel latches and rubber anti-slip pads on the bottom. It is non-toxic, odorless, UV-resistant, and resistant to discoloration. The surface is smooth and easy to clean, providing excellent insulation performance while being durable against impacts—ensuring a lifetime of use. When used in conjunction with ice packs, the cooling effect exceeds industry standards set by American counterparts. The sustained refrigeration time can last for several days.

Advantages of AHIC Cooler Boxes

1. Low Cost of Rotational Molding Tools — For products of the same specifications and size, the cost of rotational molding tools is approximately one-third to one-fourth that of blow molding or injection molding tools, making it suitable for large plastic products.

2. Superior Edge Strength in Rotationally Molded Insulated Boxes — Rotational molding allows for edge thicknesses exceeding 5mm, effectively addressing the issue of thinner edges commonly found in hollow products.